| | Tacklin the forks! |  |

|

|

| Author | Message |

|---|

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Tacklin the forks! Subject: Tacklin the forks!  Tue Apr 07, 2015 10:12 am Tue Apr 07, 2015 10:12 am | |

| About to launch into the task of replacing the front fork seals. Only the left seal is leaking but i may as well replace them both while im at it as they have both travelled the same distance. Im going to use Cosmic Jumpers method and try to extract the seal without totally dismantling the shock. I have a couple questions before i start! I will change the oil in both forks, how do I measure the oil level- Do i measure the oil with the smooth shaft part pushed as far as possible into the body of the shock, once the spring is removed? 97mm to the oil? Second question is- how much pressure is on the retaining nut that holds the spring in? Will it send me to the moon as I unscrew it or at least remove a finger?

After reading some posts here on shock ideas I think I will use 20w oil and shim the spring about a 1/4 inch! Can't afford the $200+ for the Progressives right now- its been a long cold winter! |

|

| |

Chilliwing

Maxi-Scooter Rider

Number of posts : 146

Age : 68

Location : Chilliwack, British Columbia, Canada

Points : 5000

Registration date : 2011-09-03

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 07, 2015 11:12 am Tue Apr 07, 2015 11:12 am | |

|

It's too bad you can't do the Progressive Springs replacement as in my opinion it was with out a doubt the best modification to vastly improve the handling of the Swing.

I had my springs done at a shop so I can't offer any help with respect to oil level and spring removal. Good luck with the job and I hope all goes well.

I won't tell you about our winter!

|

|

| |

Lazyfox

Scooter Rider

Number of posts : 24

Location : Poland (somewhere in Europe)

Points : 3545

Registration date : 2015-04-07

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 07, 2015 1:25 pm Tue Apr 07, 2015 1:25 pm | |

| - Chilliwing wrote:

It's too bad you can't do the Progressive Springs replacement as in my opinion it was with out a doubt the best modification to vastly improve the handling of the Swing.

I had my springs done at a shop so I can't offer any help with respect to oil level and spring removal. Good luck with the job and I hope all goes well.

I won't tell you about our winter! Could not agree more. I was about to sell straightaway my SW due to a wobble front suspension. The HyperPro springs are even a better mod than Givi AirFlow screen IMHO. |

|

| |

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 07, 2015 3:05 pm Tue Apr 07, 2015 3:05 pm | |

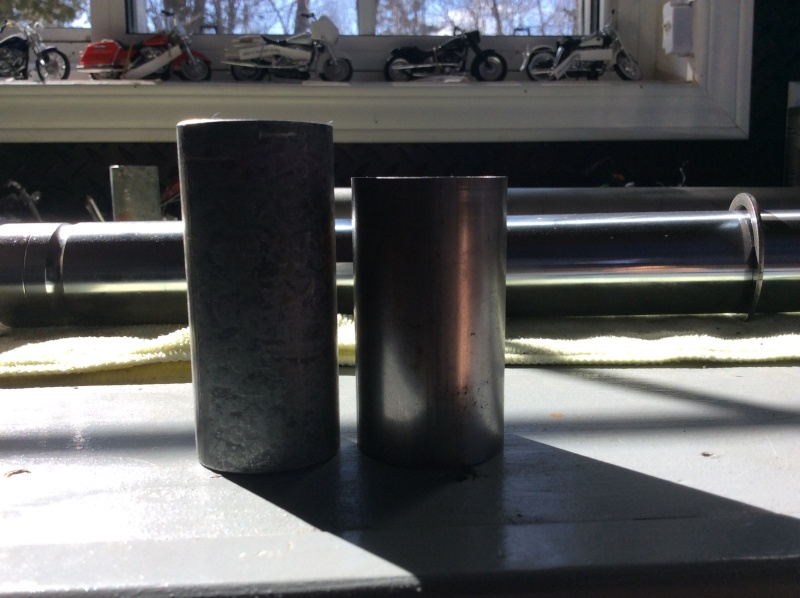

| Its taken me about 45 minutes to get to this stage. So far so good.  |

|

| |

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 07, 2015 4:36 pm Tue Apr 07, 2015 4:36 pm | |

| Couldn't wait for an answer. Cosmic jumper I tried the 'screw in the seal' to remove thing but it wouldn't work for me, so i ended up taking one shock apart so far. No big deal to dismantle. Took me around 15 minutes. I think the second one will take me 5. The end cap holding the spring in was not under a whole lot of tension and removing the 22mm end nut was no safety issue.  |

|

| |

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Mon Apr 13, 2015 8:46 pm Mon Apr 13, 2015 8:46 pm | |

| Ok finished the shock rebuild. Had to order the seals and dust caps so had a few days delay. I made new shim tubes so they would be 10mm longer than the stock ones:  I also used HD heavy fork oil. I googled for some info on what weight the "heavy" oil was and its 15w according to most. The HD dealer didn't know! Wanted 20w but no one had it in stock and didnt want to order it and have another delay. All dealers and part stores had the 5w and the 10w but no 20w!  No problems with the reassembly. No need for special tools to seat the new seals. I just used a flat round punch and tapped the seal gently into place working slowly around its circumference. As I poured in the new oil by comparison i could see the old oil was extremely dirty! Total time to dismantle and reassemble everything back on the bike was around 3.5 hours. Took the bike for a test run. Conclusion: rides a lot better, was worried the extended shim tubes and the heavier oil would make it into a pogo stick but its perfect. The front end seems more rigid and no more bottoming out. While i had the time and tools out i changed the oil/filter and the engine coolant. The coolant was ten years old but still looked green as new. Don't think I would have bothered changing it if i had known beforehand it was still as new. Changing it was a messy job. All maintenance done. Took the wife for a ride around the block to officially kick off our riding season..... |

|

| |

model28a

Silver Wing Guru

Number of posts : 2085

Age : 71

Location : St.Pete.FL.

Points : 7558

Registration date : 2010-02-03

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Mon Apr 13, 2015 10:10 pm Mon Apr 13, 2015 10:10 pm | |

| |

|

| |

Cosmic_Jumper

Site Admin

Number of posts : 4415

Age : 81

Location : damn near Philadelphia, PA

Points : 10745

Registration date : 2009-06-12

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 14, 2015 4:46 pm Tue Apr 14, 2015 4:46 pm | |

| - hotwings wrote:

- Couldn't wait for an answer. Cosmic jumper I tried the 'screw in the seal' to remove thing but it wouldn't work for me, so i ended up taking one shock apart so far. No big deal to dismantle. Took me around 15 minutes. I think the second one will take me 5. The end cap holding the spring in was not under a whole lot of tension and removing the 22mm end nut was no safety issue.

Thanks so much for your excellent pictorial on the front forks. I am sure that your post will inspire confidence in others who may be faced with replacing a fork seal. Can you please explain how you got the fork tube(s) disassembled. It had previously been cautioned that it was very 'touchy' trying to remove the inner cartridge from the outer fork tube and that, ultimately, it actually wasn't necessary to disassemble things that far just to replace the fork seal. Here you've gone and done it and made it look easy to boot. Now the the weather is changing for the better, and you'll be able to put down some miles, we'll look forward to more feedback from you regarding your Poor Man's Hyper Pro upgrade. Tim |

|

| |

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Tue Apr 14, 2015 7:23 pm Tue Apr 14, 2015 7:23 pm | |

| To dismantle the forks/shocks was very easy for me. I will try my best to explain:

1) place bike on double stand. Jack the front of bike off the ground and support it.

2) remove brake caliper, tire, fender. Shocks are now hanging freely. Let the caliper hang on its hoses. No need to remove the fairing.

3) use a 14mm socket to remove the bolts holding the shocks under the fairing.

4) hang onto the shock so it wont drop to the floor as you remove the bolts.

5) you will need a workbench with a vise to proceed

6) ALWAYS use a cloth or wood in your vise to protect your expensive shock. I repeat ALWAYS!!

7) clamp the body of the shock in the vise and loosen but dont remove the 8mm allen bolt on the bottom while its still pressurized.

8 ) with it still in the vise remove the dust cap and the seal retaining clip with a small screwdriver.

9) now clamp the chrome shaft of the shock in the vise. Use EXTRA CAUTION HERE AS NOT TO SCRATCH THE SHAFT WITH THE VISE. Clamp with the shock tipped upright as much as possible to prevent the oil from running all over your bench and floor.

10) use a 22mm socket to remove the top nut of the shock. This nut is under pressure from the spring inside but not a big deal. Just place your hand over the rachet to hold it all in place. It will only extend about two inches when released.

11) remove the shim tube, washer, spring and collar.Remove shock from vise to pour the oil into a container.

12) reclamp the body of the shock back in the vise

13) now dont panic here. You have to get something to stop the lower plunger on the inside of the shock from spinning to continue removing the 8mm allen bolt in step 7. I used my large rachet handle as it had a knurled handle. I think a wooden broom handle would work as well. Whatever works for you will need to be pushed hard while you finish removing the 8mm allen bolt. You can do it!

14) with the bolt removed now yank a few times to remove the main shaft out of the body, the seal will come with it.

15) slide the seal off the shaft along with the washer.

16) have a coffee, your half way there, now wipe all the parts clean to start the reassembly!

17) slide the guts of the shock back into the body thats clamped in the vise. Use the same procedure to stop the inside plunger from turning while you install the bottom 8mm bolt. Seems like once it starts to tighten you wont need to hold it from spinning.

18) now tap the top collar back into the body of the shock. I used a piece of 1 1/2 inch poly pipe split to slide over the shaft of the shock.

19) replace the large washer. Slide the new seal onto the shaft with the seals writing up and gently tap into place using a bluntnose punch and working around its circumference. I didn't have luck with the split poly pipe as it seemed to tip the seal on a possible damaging angle. Replace the snap ring. Install the new dust seal.

20) clamp the shock body upright, now push the shaft all the way down and pour in new oil (your choice of weight) till it measures 97mm from the top of the shaft to the top of the oil. Slide the shaft up and down to remove air bubbles before measuring!

21) replace the spring (the end with the tighter coils points up, open coils slides into the shaft first)

22) carefully place the shock on the floor and replace the washer and the shim tube (or the "new" extended ones as i did). Now with the cap nut in your palm push down and turn to start the nut. Took me a few tries to get this. Had to use a glove on my hand to help ease the pressure on my palm. Tighten the nut as much as possible by hand.

23) return the shock to the vise. Clamp the shaft tightly and tighten the cap nut with the 22mm socket.

24) now repeat the procedures on the second shock.

25) before you reinstall on the bike take note of the little groove about a 1/2 inch down on the shaft!? Not the groove for the bolt but the little one above it!! flush this little groove up with the top of the fork mounts. I had to use a flashlight to see that this groove was perfectly flush with the top of the fork underneath the fairing.

26) reinstall the shocks. Pushing the shock up gently will help you turn that top bolt.

27) reinstall everything else you removed

28) CHECK AND DOUBLE CHECK THAT YOU HAVE TIGHTENED EVERYTHING.

29) test ride

30) enjoy the fruits of your labor and a job well done.

I think i have covered everything. It may read complicated with all the steps but I found it an easy mod/repair. Good luck! |

|

| |

Chilliwing

Maxi-Scooter Rider

Number of posts : 146

Age : 68

Location : Chilliwack, British Columbia, Canada

Points : 5000

Registration date : 2011-09-03

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Wed Apr 15, 2015 10:28 am Wed Apr 15, 2015 10:28 am | |

| I'm impressed, well done and well explained.  |

|

| |

Cosmic_Jumper

Site Admin

Number of posts : 4415

Age : 81

Location : damn near Philadelphia, PA

Points : 10745

Registration date : 2009-06-12

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Wed Apr 15, 2015 12:29 pm Wed Apr 15, 2015 12:29 pm | |

| So in step 13 is the idea to just get something to wedge into the ID of the plunger so that it kind of acts as a brake to keep the plunger from turning at the same speed as that 8mm bottom bolt?

Did you use hand tools or an air or electric screw gun to remove that 8mm bolt?

Do you recall whether the ID of that plunger was smooth, like a tube, tapered, or maybe hex shaped so that a tool could be used to hold it in place. Seems to me that the manufacturing assembly process would require som sort to a tool to hold that plunger in place for assembly.

Tim |

|

| |

hotwings

Silver Wing Expert

Number of posts : 876

Age : 54

Location : Ontario

Points : 5566

Registration date : 2012-04-29

|  Subject: Re: Tacklin the forks! Subject: Re: Tacklin the forks!  Wed Apr 15, 2015 6:08 pm Wed Apr 15, 2015 6:08 pm | |

| - Cosmic_Jumper wrote:

- So in step 13 is the idea to just get something to wedge into the ID of the plunger so that it kind of acts as a brake to keep the plunger from turning at the same speed as that 8mm bottom bolt?

Did you use hand tools or an air or electric screw gun to remove that 8mm bolt?

Do you recall whether the ID of that plunger was smooth, like a tube, tapered, or maybe hex shaped so that a tool could be used to hold it in place. Seems to me that the manufacturing assembly process would require som sort to a tool to hold that plunger in place for assembly.

Tim Yes you have to find something to stop the lower plunger from turning (not the main shaft). Im thinking its fairly smooth with maybe a little cupping, and the oil don't help. I learned from my mistake on the first shock- i didn't loosen the 8mm bolt so i struggled a little to get it started. I dont use air or electric tools on a motorcycle. Too easy to snap something. I like to "feel" what im wrenching on. |

|

| |

| | Tacklin the forks! |  |

|