|

| | Adjusting the air screws |  |

| | | Author | Message |

|---|

rjdoles

Maxi-Scooter Rider

Number of posts : 141

Age : 76

Location : Columbus, Ohio

Points : 4626

Registration date : 2012-09-24

|  Subject: Adjusting the air screws Subject: Adjusting the air screws  Mon Oct 07, 2013 11:40 pm Mon Oct 07, 2013 11:40 pm | |

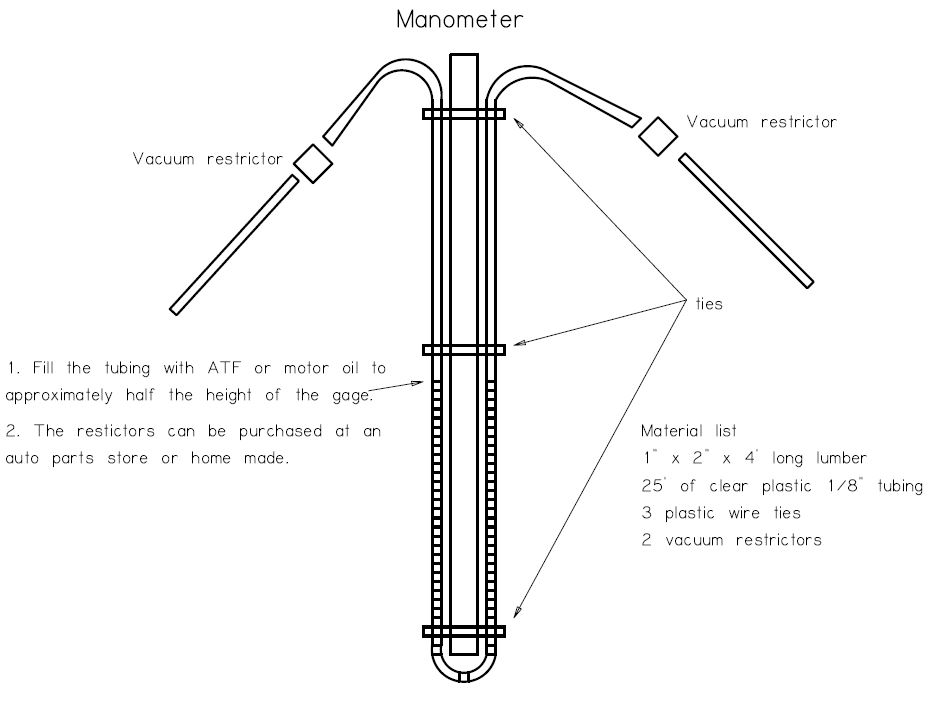

| FYI I started a thread about a month ago asking how steady the swing idle should be. I thought that mine was pretty smooth last year and after doing all the 15k service items it seemed to be surging a little. I suspected that when I tried to adjust the idle through the hole in the plastic cover under the seat, I had accidentally turned one of the air screws instead of the idle screw. The air screws set the vacuum level on the two throttle bodies. The object is to get the vacuum the same on both sides. A manometer is a pretty sensitive differential vacuum gauge. I went to Home Depot and bought 25' of 1/8 inch polyethylene tubing ($3) to make a manometer. The restrictors just slow down the movement of the oil in the manometer. Here is a cartoon of it:  I removed the plastic cover over the throttle body. I discovered that the air adjustments are slotted for a standard screwdriver. The idle screw is a plus/minus screw that would accept either Phillips or standard screwdriver. From now on any idle adjustment will only be done with a Phillips screwdriver to avoid turning the wrong screw. There are vacuum lines from both left and right throttle bodies that are connected to a tee. The third line from the tee goes over to the fuel injection vacuum sensor which is mounted over the left throttle body. I decided to remove both ends of the short piece of tubing that connected the left throttle body to the tee. I connected the manometer in it's place. The manometer is now between the left and right throttle bodies. I used motor oil in the manometer. When I started the engine, the cylinder with the higher vacuum pulled the oil up about 5 inches higher on that side of the manometer and dropped the level 5 inches lower on the other side. I decided to start from scratch and see how far out the screws were turned. I turned off the engine and counted turns as I ran the air screws all the way in. One screw was 3 turns out and the other was about 2 1/4 turns out. I ran them both out to 3 turns. I restarted the engine. The oil in the manometer was now about 2" difference in height. I adjusted one of the screws slightly to bring the oil level to about the same height on both sides of the manometer. (1/8 turn of the air screw was about 1" difference in height of the oil in the manometer) Once those adjustments were done, the idle speed was a little off. I tweaked the idle screw to get the idle speed back and life is good again. I have my steady idle back. |

|   | | Cosmic_Jumper

Site Admin

Number of posts : 4415

Age : 81

Location : damn near Philadelphia, PA

Points : 10741

Registration date : 2009-06-12

|  Subject: Re: Adjusting the air screws Subject: Re: Adjusting the air screws  Tue Oct 08, 2013 9:59 am Tue Oct 08, 2013 9:59 am | |

| Wow!, Thank you for this very helpful and clearly presented tutorial Mr Doles.

Tim |

|   | | bigbird

Silver Wing Guru

Number of posts : 2387

Location : Winnipeg

Points : 7903

Registration date : 2010-05-02

|  Subject: Re: Adjusting the air screws Subject: Re: Adjusting the air screws  Tue Oct 08, 2013 10:15 am Tue Oct 08, 2013 10:15 am | |

| I'd like to add that the service manual is a bit contradictory in their description of throttle synching. They say that the reference cylinder is #1 (the left cylinder, as seen from sitting on the seat), yet they also say to lower the higher vacuum reading down to that of the lower reading. I have synched 4 different Swings, and my best results are always to first adjust the idle screw to 1400 rpm, then lower the higher vacuum reading down to match the lower, regardless of cylinder, and then re-adjust the hot curb idle back to 1300 + or - 100 rpm. I like to go to the higher idle spec, around 1400, as the Swing engine idles low after a hot soak. Also, make sure and blip the throttle after EVERY screw adjustment, wait about 30s, and then evaluate your adjustment. It takes a lot of time for the vacuum readings to stabilize.

BTW, on a fuel injected engine it's the throttle stops on each plate that are being individually adjusted. Air screws are used on carbureted engines to adjust the pilot (idle) or main jets.

That's my $.02 on the procedure.

Oh, and why this thread was posted under "Introductions" is beyond me. Maybe a mod can move it where it will be seen and appreciated, under "Maintenance, Tips, and Hints". |

|   | | rjdoles

Maxi-Scooter Rider

Number of posts : 141

Age : 76

Location : Columbus, Ohio

Points : 4626

Registration date : 2012-09-24

|  Subject: Adjusting the air screws Subject: Adjusting the air screws  Tue Oct 08, 2013 10:32 am Tue Oct 08, 2013 10:32 am | |

| Blackfly posted a great pictorial series "air screw adjustment" on the swing site. He used vacuum gauges instead of a manometer. I used the pictures in his tutorial to figure out how to get the plastic cover off of the throttle bodies and to locate the vacuum lines.

I didn't have access to vacuum gauges and didn't want to spend the money on gauges that I would seldom use. This manometer is cheap and it will do the job just as well.

I made my own restrictions. I found some 3/16" diameter plastic rod and cut a couple of pieces about 3/4 inch long. I have a pin drill set and used a #80 drill which is .0135" to drill a tiny hole through it. I pushed the polyethylene tubing over these restrictions.

You still see the pulsations in the movement of the oil when a cylinders is on the intake stroke but the movement is really dampened by the restrictors. |

|   | | rjdoles

Maxi-Scooter Rider

Number of posts : 141

Age : 76

Location : Columbus, Ohio

Points : 4626

Registration date : 2012-09-24

|  Subject: Adjusting the air screws Subject: Adjusting the air screws  Wed Oct 09, 2013 11:18 pm Wed Oct 09, 2013 11:18 pm | |

| - bigbird wrote:

BTW, on a fuel injected engine it's the throttle stops on each plate that are being individually adjusted. Air screws are used on carbureted engines to adjust the pilot (idle) or main jets.

That's my $.02 on the procedure.

Oh, and why this thread was posted under "Introductions" is beyond me. Maybe a mod can move it where it will be seen and appreciated, under "Maintenance, Tips, and Hints". I agree that they are throttle stops but I called them air screws because Honda calls them air screws in the service manual. I wanted to be consistent with the manual. Maybe Honda's reasoning for calling them air screws is that the fuel is introduced downstream so the throttle plates only control the air flow. I posted a question on this site in the Silverwing Topics area about a month ago asking how steady the idle should be. I entered this follow-up in that same category. I bought the swing in October of last year with about 16k miles on it. It needed the 15k service done. I ordered the parts to do that service the next day. I only rode it about a week before the parts arrived and I was able to do the 15k service, change the tires and install 28g sliders. The idle was surging and after all the work, I felt like the idle was more stable before the work and as it turns out, it was. In other words, I have met the enemy and he is me. You made a good point about blipping the throttle after making an each adjustment to get the throttles seated. I did that after each adjustment but failed to mention anything about it. You are probably right that the thread should have been in Maintenance tips since it gets into the technical aspects of the adjustment but BlackFly had already published a great pictorial on the subject. The only difference was that his pictorial used vacuum gauges and I added a drawing on how to build a cheap manometer. If someone didn't have two vacuum gauges or didn't want to spend the $40 or more on a couple of vacuum gauges, they could build the manometer for less than $10. If there is a way to move this to the Maintenance category, that is fine with me. |

|   | | echris108

Scooter Rider

Number of posts : 27

Age : 48

Location : singapore

Points : 4101

Registration date : 2013-10-05

|  Subject: Re: Adjusting the air screws Subject: Re: Adjusting the air screws  Sat Oct 12, 2013 8:46 pm Sat Oct 12, 2013 8:46 pm | |

| hi,i remember during my younger days.someone told me to adjust my fuel/air mixture screw by listening to the exhaust sound for my single thumper.either clock or anti clockwise,there will be a midpoint when the idle will sound sweet.n when i get that point,i can lower my idle speed will low n the thumper will not die off. |

|   | | | | Adjusting the air screws |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |